SICACELL

Improves the physical and tribological characteristics of brake pad

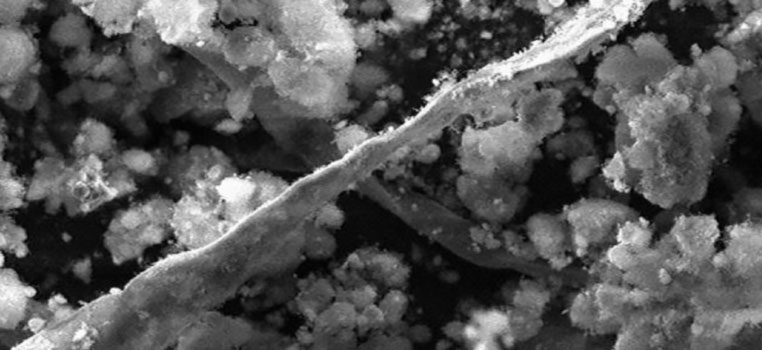

The SICACELL products are composed of hydrated synthetic calcium silicate, silica free.

TSICACELL 964 is reinforced with high purity cellulose.

Thanks to its particular morphology and its anti-segregation properties, it improves the homogeneity of the mix in composite materials.

It helps the molding process improving mechanical resistance of pre-forming.

It improves both low thermal conductivity and density to the final product.

ADVANTAGES

- Improves the dispersion of the ingredients in the mix

- Good anti-segregation property of raw materials

- Improves the affinity with the fibers and the powders in the mix

- Offers good compatibility with phenolic resin

- Improves the green strength of the pads

- Decreases the thermal conductivity of final products

- Material saving thanks to the low density and higher porosity of friction material

- Stabilizes the friction coefficient at high temperature

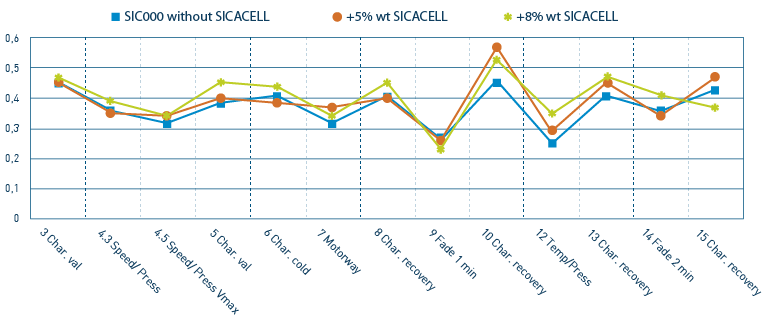

AK-Master - friction level

SICACELL used in various percentages in the production of brake pads for passenger cars and commercial vehicle helps to stabilize the friction level under heavy-duty conditions and reduces the pad wear.

Tags: ABRASIVES AND ABRASIVE GRINDERS, GASKETS, FRICTION MATERIALS, POLYMERS